How To Get Pvc Repair Coupling

In this blog post, we will discuss the importance of coupling and give you a few tips on how to get PVC repair coupling. Coupling is a critical piece of industrial equipment that helps to ensure the integrity of pipe systems. When it fails, it can lead to costly repairs and lost production. By following our tips, you can ensure that your coupling is in good condition and ready for any repairs or replacements that may come up. We hope that this article provides you with the information you need to keep your pipe systems running smoothly.

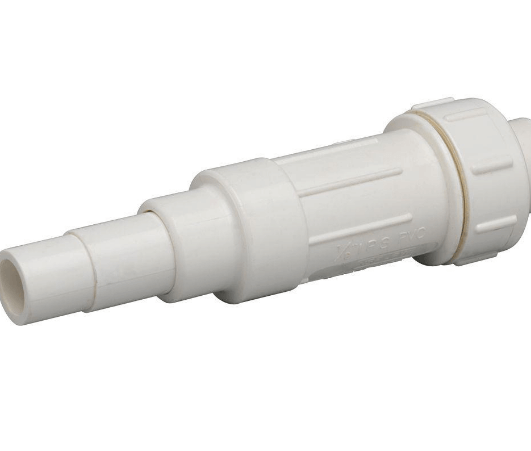

Pvc repair coupling

PVC repair coupling is a quick and easy way to join two pieces of PVC pipe together. You will need:

-A PVC coupler

-A pair of pliers

-An adjustable wrench

What is PVC coupling?

PVC coupling is a type of adhesive that’s used to join two pieces of PVC pipe. It’s also known as “snap coupling,” and it works by using pressure to create a seal between the two pieces of PVC.

The main benefit of using PVC coupling is that it’s low-cost and easy to use. You can use it to connect any two pieces of PVC pipe, and it doesn’t require any special tools or skills. Simply apply pressure to the seams, and the adhesive will create a seal.

One downside of PVC coupling is that it can be fragile. If you don’t pay attention to the dimensions or the layout, the coupling may break down over time. Additionally, PVC coupling isn’t designed for watertight connections; if there are any leaks, the adhesive will eventually wear away and the pipes will become separated.

Types of PVC coupling

There are a few different types of coupling used in PVC pipe, each with its own benefits and drawbacks. The most common type is the slip joint coupling, which uses a plastic inner pipe fitting that slips over an outer pipe. This type of coupling is easy to use and quick to install, but it can be prone to leaks. The snap-fit coupling is similar to the slip joint coupling, but it uses a metal fittings that snaps into place. This type of coupling is more durable than the slip joint coupling and less likely to leak, but it requires more time to install. The bolts-in-place coupling uses several bolts that connect the two pipes together. It’s a more difficult installation than the other couplings, but it’s also more stable and resistant to leaks.

Ways to pvc repair coupling

When repairing or replacing pvc coupling, it is always important to use the correct type of coupling. There are a few different types of coupling available on the market, and each has its own unique properties that should be considered when choosing them.

PVC couplings can be made from a variety of materials and have several different shapes. The most common type is an elbow coupling, which is made out of two pieces of PVC that are bent together at an angle. Elbow couplings require less force to secure than other types of couplings, but they also have a smaller diameter tolerance.

Another type of coupling is a T-joint coupling, which is similar to an elbow coupling in that it consists of two pieces of PVC that are bent together at an angle. However, the T-joint coupling has one extra piece that connects the two parts. This extra piece makes it easier to connect the two parts together, and it also allows for greater flexibility in the joint.

Still another type of coupling is a U-joint coupling. This type of coupling is made up of three pieces of PVC that are bent together at an angle. U-joint couplings are typically used when there is a need for greater strength and durability in the joint.

Conclusion

If you have a broken pvc coupling, there are a few different ways to repair it. You can use sealant and screws, or Loctite and screws. With either approach, make sure to remove the old seals and any debris before beginning. Next, apply a small bead of sealant to one end of the screwed piece. Insert the screw into the sealant and turn it until it is tight. Repeat on the other end. Finally, using solvent to clean up any excess liquid or debris, attach the coupling pieces together by tightening each screw evenly.